GLYCOL SYSTEM PIPING GUIDE

Read More »Why You Should Invest in Professional Chiller Maintenance Services

Discover the importance of investing in professional chiller maintenance services to ensure optimal performance and longevity of your cooling system.

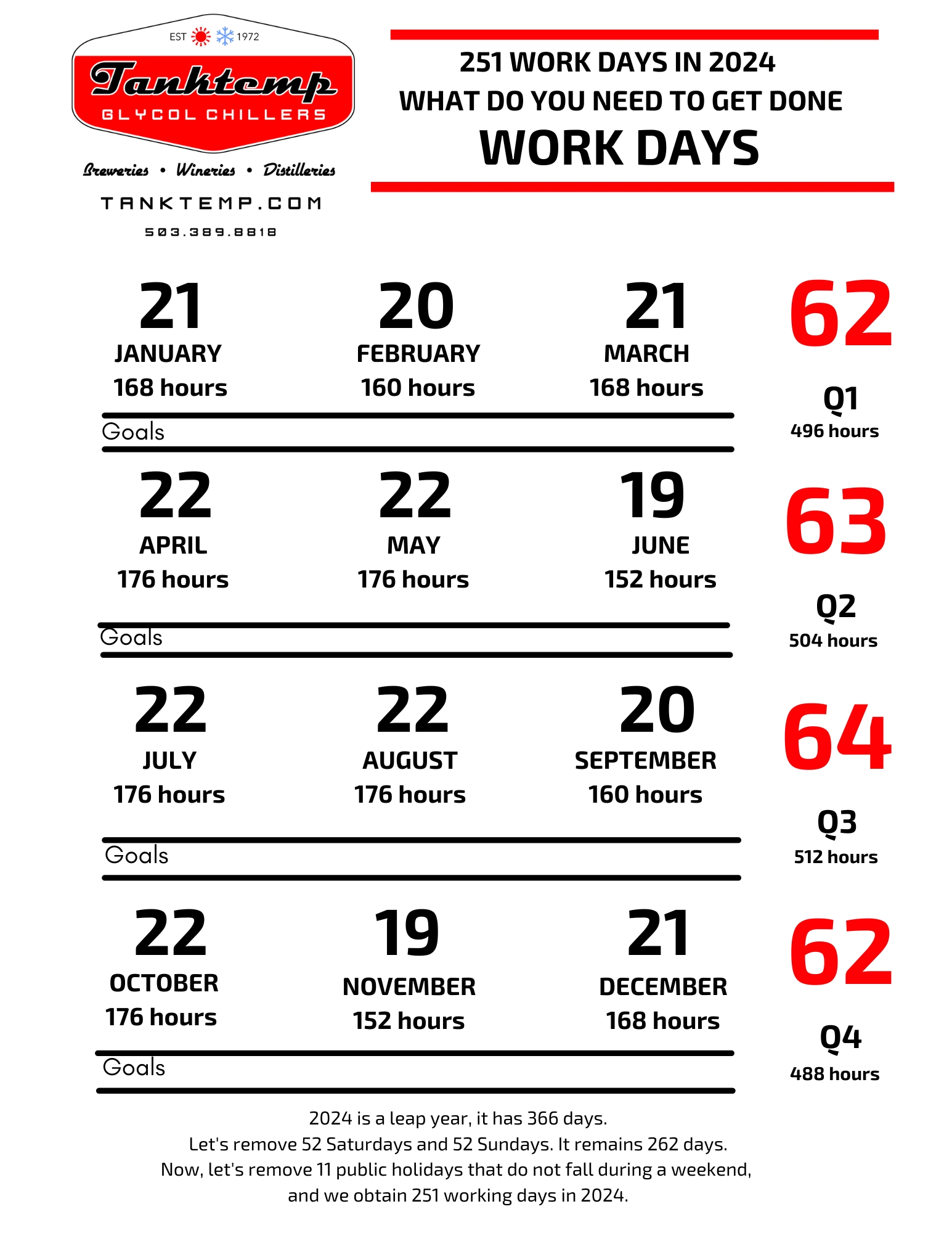

Read More »2024 Work Day Calendar

What is going on in your barrel room.

What you need to know about Glycol vs HVAC.

FAN COILS FOR COLD ROOMS, BARREL ROOMS, AND WALK-INS.

This is why you are loosing product in your barrel room

Read More »

CHILLER SYSTEM PREVENTIVE MAINTENANCE CHECKLIST Inspection

A toast to Chiller Maintenance and summer heat

Work to do something better everyday

What kind of world do you want to live in?

What I Wish I’d Known Before Starting a Brewery, Winery or Distillery

We chat with countless breweries, wineries and distilleries to see how the coronavirus is affecting them, and what we can do to help. I started working on this piece before the virus rocked the industry, and now is a great time to discuss it. This is by no means complete, but what is in this industry? So read, comment and reflect on. This article will grow, so check from time to time to see what else I’ve added.

Read More »We are all in this together. How can we help?

| The current events are impacting everyone. People first is always a good policy. The brewery, winery, and distillery communities have always banded together through fire, storms, good times, and hard times. As we always do, we will find a way to overcome the current events together. We are all in this together, and for 48 years we have been your partner and advocate as you navigate all your challenges, so if you need something, ask, we are here. All across the country, cities and states are ordering breweries, distilleries, and wineries to close to the public due to Coronavirus cases; though in some places you will be allowed to produce carryout and delivery orders. More states are likely to institute similar orders this week. How are you coping with this? What are your contingency plans and how can the community support you? We are doing, and will do, everything we can to support you all. Post ideas and suggestions on our social media pages. Obviously on-premise sales are down, however off-premise sales are way up. We are on the phones all day. every day with as many of you as we can be and this is what we are hearing. This article is mirroring most of the conversations we are having with you all. |

single-phase vs. three-phase power

Three-phase vs single-phase which do you want and why?

It all comes down to Amps, how many do you have, how many do you need and how many can you save?

Read More »What cooling is and how it works

At Tanktemp we believe that if you want something to work right, then you need to understand how it works.

Read More »LET US SHOW YOU WHERE THE TIME GOES

LET US SHOW YOU WHERE THE TIME GOES

Let us show you where the time goes:

Let’s break down your year into hours and show why it is so hard to get things done. We are hearing from everyone. Where does our time go?

Everything you ever wanted to know about glycol plumbing

How you install your chiller is just as important as the chiller itself. The layout and design of a system can make all the difference. We have been installing systems since 1972.

Always plan for expansion, don't plumb yourself into a corner, make sure you can add to the system and make repairs if needed.

Glycol plumbing is what is called “process plumbing”. It goes from the chiller and back to the chiller. Generally it is not hooked to city water and you definitely don’t want it hooked to the drainage system. Glycol is not cheap.

Most of all, plan your layout and size everything to work for today and tomorrow. Tanktemp offers design and engineering services as well as full installation and maintenance.

Here is what everyone else won’t tell you.

Read More »Harvest Checklist

By May or June of next year, too much time has passed to remember all the details of the prior year’s harvest. From an operational standpoint, June is generally too late to be starting the process of preparing for harvest. The goals of building this checklist is to help prepare and be a bit more strategic. With over a decade of combined service experience in our shop, 48 of it in one guy, we have seen it all.

Read More »10 ways to reduce downtime with preventative maintenance

Downtime costs every one of us money every year. Our clients are no exception. As a matter of fact, you are all the prime example of downtime is a killer. Most are aware of the benefits of preventative maintenance in reducing planned and unplanned downtime. But what other steps can you take?

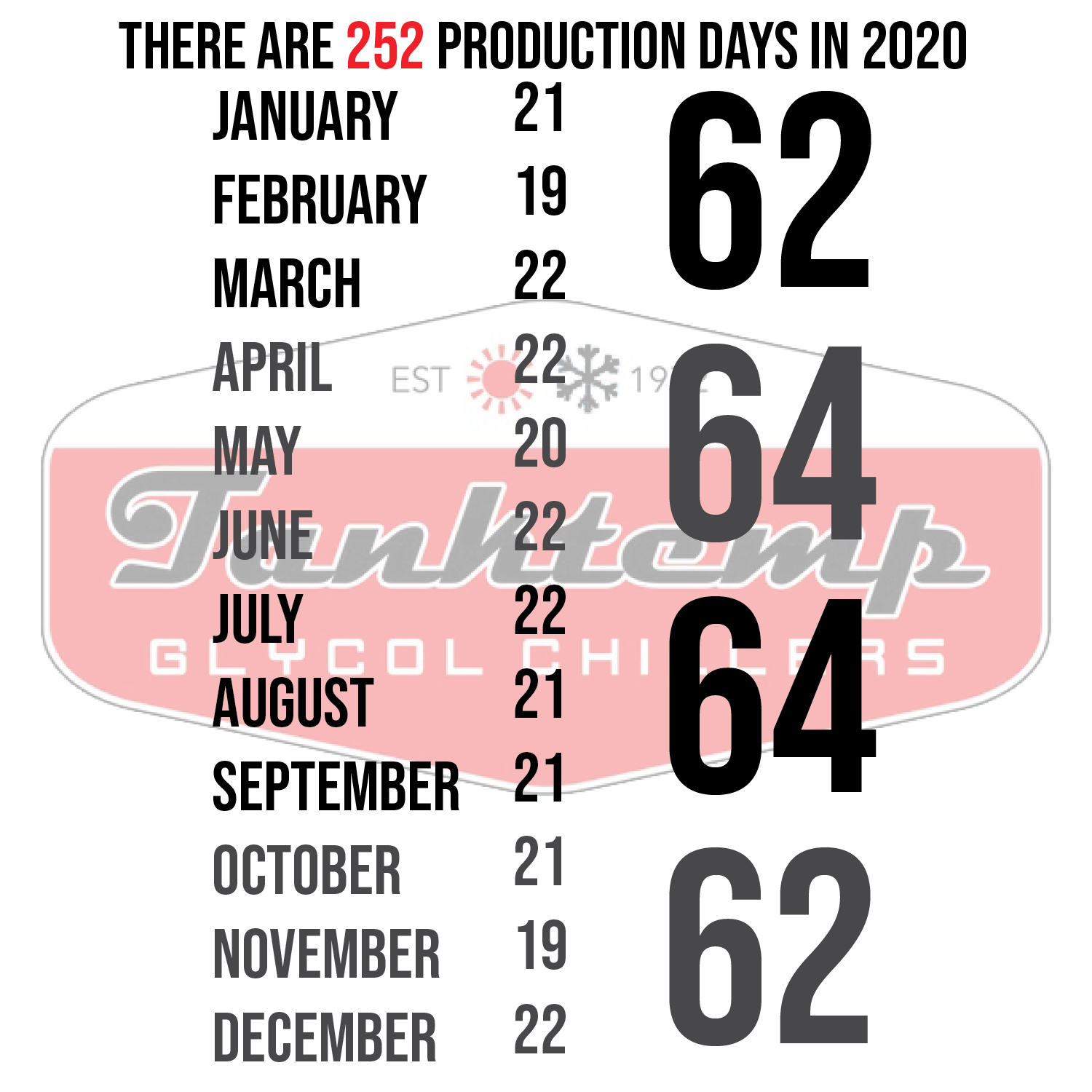

Read More »Important changes coming in 2020

We wanted to bring attention to a few things that will potentially affect your business 2020. We hope this roundup will help you cross one more thing off your mile-long December to-do list so you can enjoy that nice winter break.

Read More »R22 Freon to be banned in 2020

Refrigerant R22 (also commonly called Freon) has been used in the production of refrigeration equipment for decades. Over time, scientists have begun to realize the environmental danger of Chlorofluorocarbon (or CFCs) in refrigerants like R22, the Global Warming Potential of which contributes heavily to the depletion of the ozone layer.

Read More »GETTING THE MOST OUT OF YOUR GLYCOL EQUIPMENT

LET'S SAVE YOU SOME BUCKS!

Run your chillers harder at night and save big.

The air is cooler at night. Crash tanks at night when the air is cool. Maintain the tanks during the day and save big. This can easily save up to 20% of overall cooling energy.

Nighttime building cooling.

Bring in low-temperature night air to cool the building further.

Tank insulation.

Spray-on, foil-covered bubble wrap, and rigid foam all work. This can reduce refrigeration cost by 15-60%.

CHILLER SIZING WORKSHEET

HOW DO YOU EVALUATE A CHILLER?

How do you evaluate a chiller? Not all chillers are created equal.

As a matter of fact, over 90% of chillers made don’t have the capacity a brewery, winery or distillery needs. There are a lot more computer rooms, fab shops, buildings, equipment and lasers in the world that need to be maintained at 60°F than there are breweries, wineries and distilleries. So you need to know that is what most manufacturers build for, and they try to force those units to work in our environments.

Read More »